Why Do High-Performance Cars Prefer DOT 4 Class 4 Brake Fluid?

Introduction

Many people perceive brake fluid as merely a consumable item requiring regular replacement, seemingly unworthy of much attention. However, during emergency braking on highways, the high temperatures of continuous downhill driving, and the instantaneous intervention of ABS and ESP systems to control vehicle posture, what truly determines braking reliability is often that seemingly ordinary fluid – DOT 4 Class 4 Brake Fluid.

What makes it different? Why are more and more car models explicitly recommending the higher-grade DOT 4 products? Understanding these questions is not only about technology selection but also about driving safety itself.

From "Usable" to "Safer": The True Value of DOT 4 Class 4

The DOT standard originates from the U.S. Department of Transportation and is a globally widely adopted brake fluid performance specification. DOT 4 is already considered high-grade, while Class 4 represents a product category that emphasizes stability and overall performance within the DOT 4 framework.

Hydraulic Principle of Braking

The core principle of a braking system is hydraulic transmission. When a driver presses the brake pedal, pressure is transmitted through the brake fluid to the brake calipers, and then by the brake pads to the brake discs. Theoretically, liquids are incompressible, thus allowing for precise pressure transmission. However, if the brake fluid boils at high temperatures, producing bubbles, it becomes compressible, causing the pedal to soften and even resulting in brake fade—this is known as "vapor lock".

The significance of DOT 4 Class 4 Brake Fluid lies in its stability under extreme conditions. It typically exhibits higher and more consistent dry and wet boiling points. Especially after absorbing moisture, the boiling point drops less, maintaining reliable performance over long-term use. This "long-term stability" is precisely the core value of Class 4.

Long-Term Corrosion Control

The braking system is not composed of a single material. Cast iron, steel, aluminum alloys, copper, and various rubber seals coexist in a closed yet complex environment. Brake fluid circulates within this environment for years, and if the anti-corrosion system is inadequate, internal corrosion can occur.

Especially in humid environments, the risk of corrosion increases significantly after the brake fluid absorbs moisture from the air. The ABS module, cylinder inner walls, and pipe joints can all be damaged. This can range from affecting braking response to increasing repair costs.

DOT 4 Class 4 Brake Fluid is valued for its enhanced antioxidant and rust-preventive additive system. This formulation focuses not only on short-term performance but also on extending system life. This long-term stability is particularly important for fleet operations, high-end vehicles, and export markets.

Performance in the Era of Electronic Braking

Past mechanical braking systems had relatively simple requirements for fluid flow. Today, electronic control systems such as ABS, ESP, and EBD require brake fluid to complete high-frequency flow and pressure changes in a very short time.

If the viscosity is too high at low temperatures, the fluid flow will be sluggish in cold environments, affecting the response speed of electronic systems; if high-temperature stability is insufficient, it will lead to the risk of pressure fade. Therefore, DOT 4 Class 4 is not just about a "higher boiling point," but about achieving a more precise balance between high and low temperatures.

This performance balance requires strong formulation development and production control capabilities, rather than simply adding basic raw materials.

Why Choosing a Professional Manufacturer is Crucial

Brake fluid is a safety-related product. While differences in formulation may not be immediately noticeable, they can become apparent over long-term use. Therefore, a supplier's technological expertise and quality management system are crucial.

Hangzhou Jialibang New Materials Co., Ltd. has over 20 years of experience in high-performance chemical materials. The company focuses on the research and development of high-performance sealants and adhesives, including silicone sealants, RTV sealants, and epoxy AB adhesives, which are also used in the automotive, construction, electronics, and photovoltaic industries.

This cross-disciplinary accumulation of materials technology gives us a solid foundation in fluid stability, material compatibility, and anti-aging systems. As a Chinese supplier and exporter of PINSU-DOT4 Brake Fluid with Anti-Rust Protection, we not only focus on meeting standards but also emphasize sustained stability under complex environments.

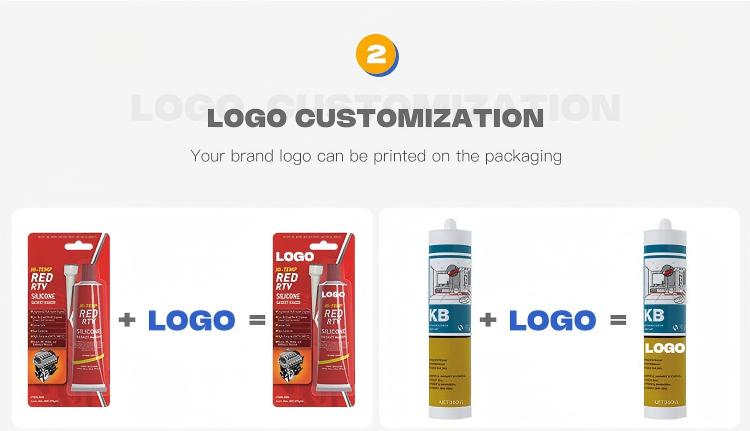

Our products are certified to international standards and we offer OEM/ODM customization services based on different national regulations and customer needs. From formulation optimization to packaging design, from technical support to bulk export, we are committed to providing stable and reliable solutions for the global market.

In the context of increasingly sophisticated global automotive industry practices, a supplier's R&D capabilities and quality control systems are often more decisive than price alone.

Market Trends: From Compliance to Performance Upgrades

With the increasing proportion of new energy vehicles and high-performance vehicles, the load on braking systems continues to rise. Electric vehicles, due to their heavier batteries, place higher demands on the durability of their braking systems; the widespread adoption of intelligent driving systems also imposes more stringent standards on braking response.

Under this trend, DOT 4 Class 4 Brake Fluid is gradually becoming the mainstream choice, no longer an exclusive feature of high-end models. Market focus has also shifted from "compliance with standards" to "higher safety redundancy."

This means that the future development direction of brake fluid will place greater emphasis on hydrolysis resistance, long-term stability, and environmental performance. High-quality products will gain wider recognition in the global market.

FAQ

Q1: Can DOT 4 Class 4 be mixed with regular DOT 4?

They are compatible in emergency situations, but to ensure optimal performance, it is recommended that the entire system use products of the same class.

Q2: Why does brake fluid absorb water?

Most DOT 4 brake fluids are glycol ether-based and hygroscopic, a property determined by their chemical structure. This hygroscopic nature helps prevent water droplet buildup, but it also lowers the boiling point, necessitating periodic replacement.

Q3: How often should I change it?

It's generally recommended to change it every two years or approximately 40,000 kilometers, but this should be adjusted based on vehicle usage conditions and the manufacturer's recommendations.

Q4: Are there special requirements for DOT 4 Class 4 in export markets?

Different countries may have different testing standards. Choosing a supplier with international certifications and customization capabilities is particularly important.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى

TOP

TOP