**FEATURES**

-1、High-temperature resistance: It can withstand high-temperature environments such as engines and exhaust systems (usually above 200℃, and some products can reach over 400℃).

-2、Strong sealing performance: Fills minor flaws on the metal surface, and is resistant to oil, water, and gas leakage.

-3、Gasket-free: Directly replace traditional solid gaskets, simplify assembly, and reduce the risk of leakage points.

-4、Shock-resistant and aging-resistant: Adapt to the vibration of components and long-term cold and hot cycles, providing long-lasting sealing.

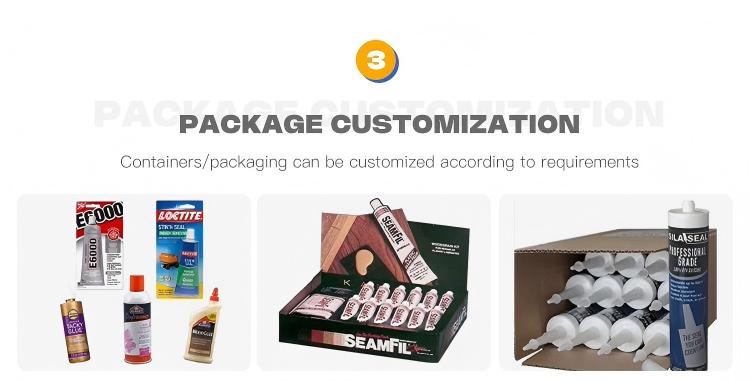

**PACKAGING**

- 300ml、120ml、85ml、70ml、50ml、35ml、10ml

-Also available in larger buckets for professional use

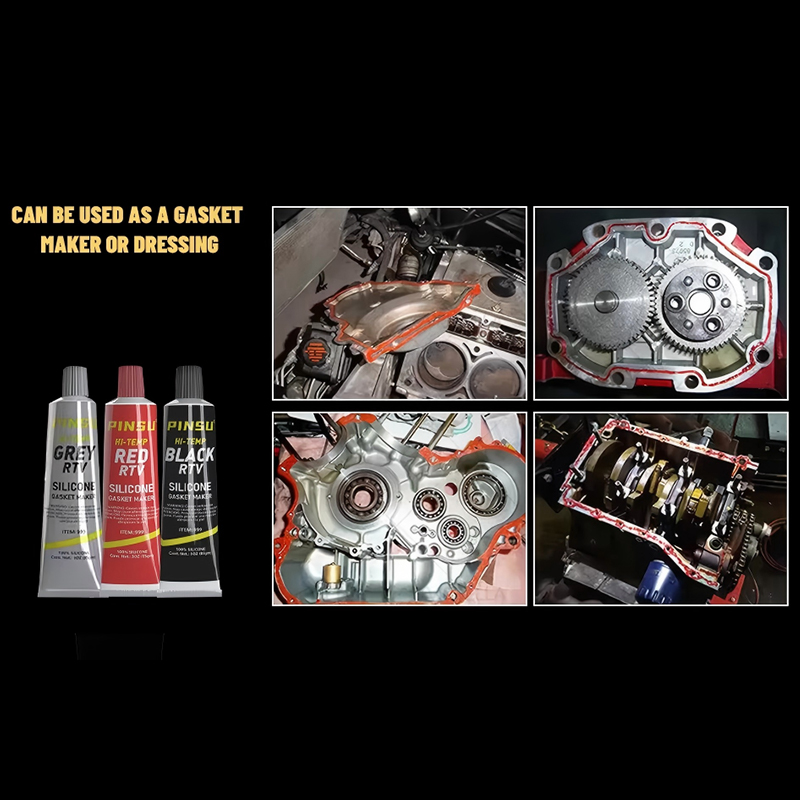

**BASIC USES**

-1、Engine: Valve cover, oil pan, timing chain cover, and other mating surfaces.

-2、Exhaust system: Exhaust pipe interface, three-way catalytic converter connection.

-3、Turbocharger: Intake pipe, housing joint.

-4、Transmission: Housing mating surface (for some applicable models).

|

|

|

High Temperature Resistant Gasketless Sealant for Automobiles Product Introduction

1. Product Overview

High-temperature resistant gasket-free sealant for automobiles is a single-component or two-component sealant designed specifically for high-temperature environments. It is used to replace traditional gaskets, forming an elastic seal directly on metal joint surfaces. It is suitable for sealing high-temperature, high-pressure areas such as engines, gearboxes, and exhaust systems, and has excellent temperature resistance, oil resistance, and anti-aging properties.

2. Product Features

✔ High-temperature resistance: Long-term temperature resistance range of -40°C to +300°C (short-term up to +350°C).

✔ Gasket-free design: Directly applied to the sealing surface, it forms a flexible sealing layer after curing, replacing traditional metal/rubber gaskets.

✔ Medium Resistance: Resistant to chemical corrosion from engine oil, gasoline, diesel, coolant, acids, and alkalis.

✔ High Elasticity: Retains flexibility after curing, accommodating vibration and thermal expansion/contraction.

✔ Rapid Curing: Some products support room-temperature curing (24 hours) or accelerated curing via heating (e.g., 80°C for 1 hour).

3. Typical Applications

Engines: cylinder heads, oil pans, timing chain covers, turbocharger seals.

Transmissions: housing mating surfaces, side cover seals.

Exhaust systems: exhaust pipe flanges, catalytic converter interfaces.

Other high-temperature areas: EGR valves, intake manifolds, water pump seals.

4. Technical parameters (based on typical products)

| Item | Parameter |

| Color | Gray, red, or black (depending on the brand) |

| Viscosity | Paste-like or semi-fluid (suitable for scraping or spraying) |

| Curing Method | Moisture curing or heat curing |

| Shear Strength | ≥5 MPa (steel - steel, after curing) |

| Pressure Resistance | Sealing pressure resistance ≥10 bar (static) |

| Applicable Substrates | Metals such as cast iron, aluminum, steel, stainless steel, etc. |

5. Application Method

1. Surface Preparation:

Thoroughly clean the sealing surface, removing oil stains and rust (recommended to use acetone or a specialized cleaner).

Roughening the surface (e.g., by sanding with sandpaper) can enhance adhesion.

2. Adhesive Application:

Apply the adhesive evenly to the sealing surface (thickness: 0.1–0.3 mm; no need for excessive thickness).

Application methods include scraping, brushing, or using specialized dispensing equipment.

3. Assembly:

Immediately close the components and tighten the bolts (some products require assembly within 5 minutes after adhesive application).

Tighten the bolts in a diagonal sequence to the specified torque.

Curing:

Room temperature curing: reaches service strength in 24 hours.

Heat acceleration: preliminary curing at 80°C for 1 hour (refer to product specifications for details).

6. Advantages over traditional gaskets

| Comparison Items | Gasket - free Sealant | Traditional Gasket |

| Sealing Performance | Fills microscopic unevenness, no risk of interface leakage | Relies on gasket compression, prone to aging and failure |

| Temperature Resistance | Can reach above 300°C | Rubber gaskets usually have a temperature resistance of ≤200°C |

| Vibration Resistance | Elastic to adapt to vibration, not easy to loosen | Metal gaskets may leak due to vibration |

| Cost and Efficiency | Eliminates the need for gasket procurement and inventory, simplifies assembly | Requires matching gasket models, cumbersome installation |

7. Precautions

⚠ Safety precautions:

Avoid contact with skin or eyes (contains silicone or epoxy components, which may cause irritation).

Work in a well-ventilated area, away from open flames (some products contain solvents).

⚠ Restrictions on use:

Not suitable for plastic or non-metal surfaces (compatibility must be confirmed).

For large gaps (>0.5mm), use with metal gaskets.

8. Frequently Asked Questions

Q1: Can it be used for exhaust manifold sealing?

→ A high-temperature resistant sealant (≥500°C) must be selected, such as ceramic-filled products.

Q2: How to disassemble after curing?

→ Mechanical tools can be used to separate, and residual adhesive layers can be cleaned with a scraper or solvent (such as acetone).

Q3: How long after application can the engine be started?

→ It is recommended to cure for at least 12 hours at room temperature or follow the manufacturer's instructions for heat curing before pressurizing and operating.

High-temperature resistant gasket-free sealant for automobiles simplifies the assembly process and enhances sealing reliability, gradually replacing traditional gaskets. When selecting a product, it is essential to match it to specific operating conditions (temperature, medium, pressure) and strictly adhere to the application process to ensure effective sealing.

ENG

ENG

English

English 中文简体

中文简体 русский

русский Español

Español عربى

عربى

TOP

TOP